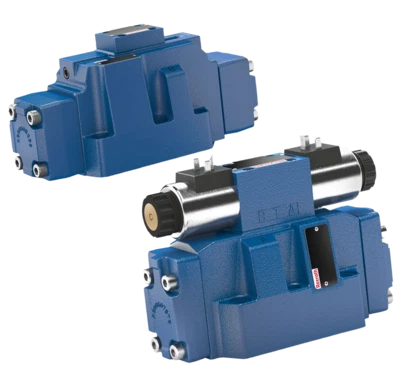

Bosch Rexroth 4WEH Valve

Description:

share:

Product Details ofBosch Rexroth 4WEH Valve

Bosch Rexroth 4WEH reversing coil valve

The Bosch Rexroth 4WEH reversing hydraulic valve is an adaptable and reliable hydraulic valve designed for mounting baseboards. It is designed to regulate hydraulic oil flow in a variety of industrial applications, providing flexibility and high efficiency for seamless system integration. The 4WEH model is widely acclaimed for its durable construction and versatility, making it the first choice for challenging hydraulic environments.

Main features:

Power Supply: The valve is compatible with 12 V or 24 V DC, allowing multiple power options to meet different system requirements.

Power consumption: 4WEH valves consume up to 2 A of current, ensuring efficient performance and minimizing energy consumption.

Connection standard: It has DIN EN 175301-803 connections and can be easily integrated into standard hydraulic systems.

Protection Class: 4WEH valve protection class IP65, with strong dust and water resistance, to ensure durable reliability and performance in harsh industrial environments.

Technical specifications:

Valve function: As a directional valve, 4WEH is designed to effectively control and direct fluid flow in the hydraulic circuit.

Control options: The valve can be equipped with hydraulic or electro-hydraulic control options to provide precise and responsive flow control for a variety of applications.

Flow path configurations: Available in 3/2, 4/2 and 4/3 configurations, the valve provides the flexibility to create hydraulic systems with multiple flow paths.

Size variants: Available in NG10, NG16, NG25 and NG32 sizes, the valve can be customized to meet specific flow and system requirements.

Pressure capacity: 4WEH valves can withstand operating pressures of up to 350 bar, making them suitable for high-pressure applications with demanding performance conditions.

Flow rate: The valve is capable of handling flow rates of up to 1100 litres per minute and is designed for systems requiring high fluid capacity.

Centering mechanism: A variety of centering options are available, including spring, pressure and hydraulic centering, allowing tailor-made to meet specific system requirements.