High Response Rexroth Valves

Description:

share:

Why Choose High-Response Rexroth Valves

-

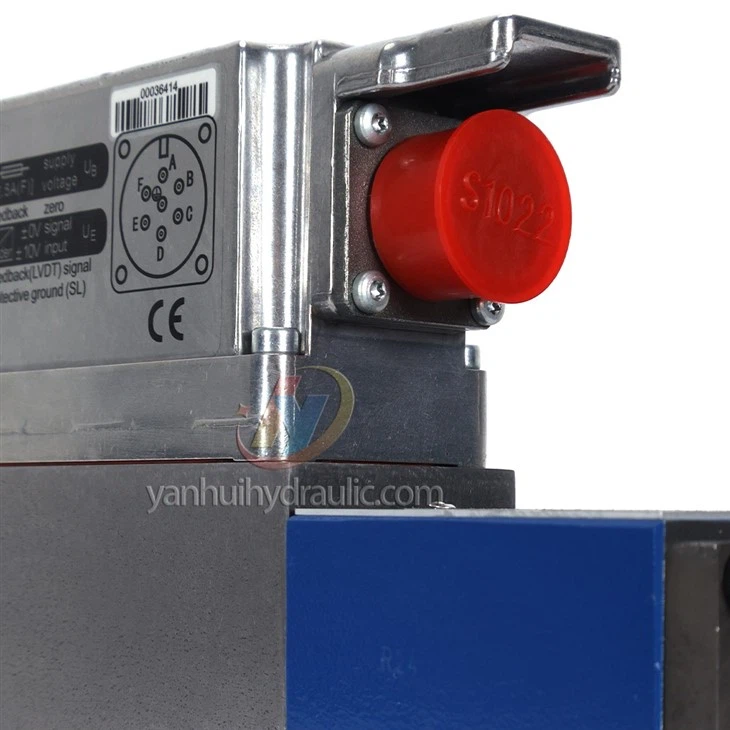

High dynamic response & precision control: Thanks to servo-quality spool/ sleeve design, integrated electronics, and position feedback, these valves deliver precise, repeatable control of flow/pressure with minimal hysteresis and drift.

-

Flexible configuration & scalability: Multiple valve sizes and types (direct-operated / pilot-operated; 3-way, 4-way; various flow capacities) allow selection tailored to system requirements.

-

Stable performance under high pressure and load: Valves provide robust performance up to ~315–350 bar, suitable for heavy-duty industrial & mobile hydraulic systems.

-

Integrated electronics & easier system integration: On-board electronics (OBE) simplify control setup, reduce wiring complexity, and boost reliability; some models support digital interfaces (e.g. IO-Link / integrated axis controller) — advantageous for automation / modern control environments.

-

Wide application range: From machine tools and plastic injection molding to heavy machinery, presses, and automated production lines — suitable wherever fast, accurate hydraulic actuation is needed.

-

Low maintenance and long service life: Servo-quality components and robust design reduce wear; built-in electronics improve consistency and reduce drift, extending operational life.