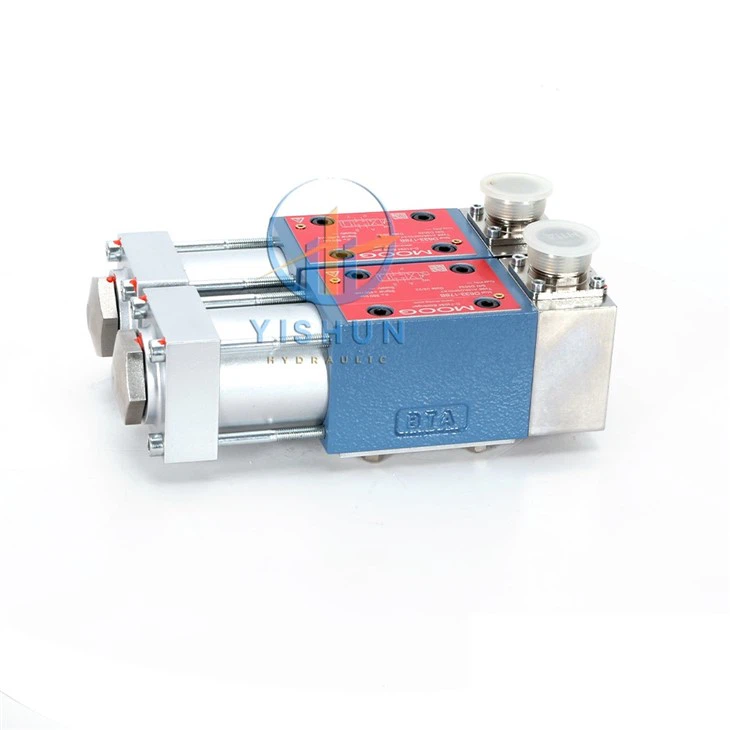

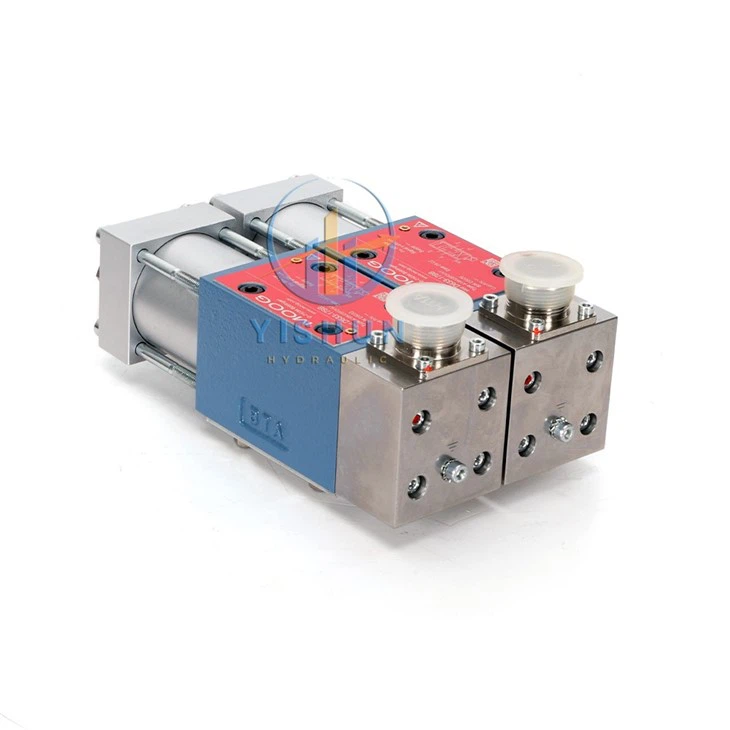

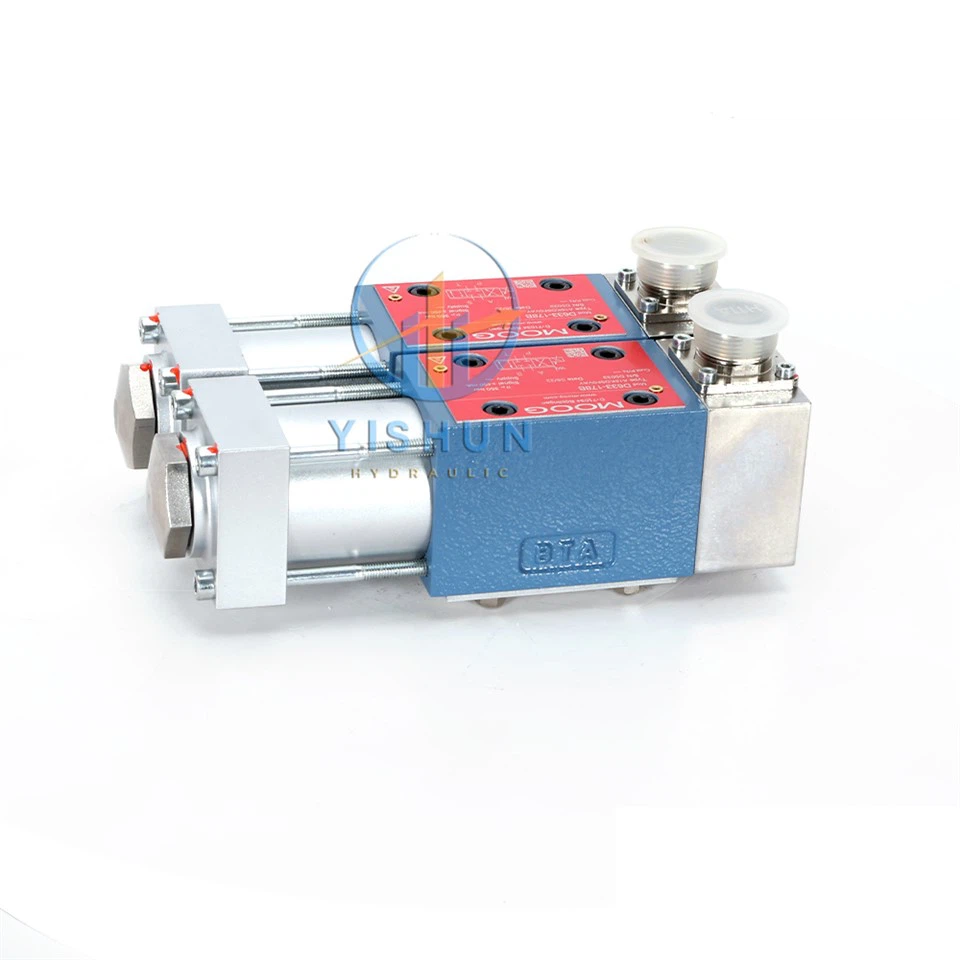

Moog D633-7105 Valve

Description:

share:

Advantages of the Moog D633-7105 Valve

-

High Dynamic Response – Fast and accurate control for advanced motion systems.

-

Excellent Repeatability – Precision spool and flapper mechanics guarantee stable, consistent performance.

-

Low Hysteresis – Ensures accurate flow regulation even under fast-changing load conditions.

-

Robust & Durable Design – Engineered for continuous duty with long service life in demanding environments.

-

Wide Application Range – Compatible with high-pressure hydraulic systems and precision industrial equipment.

- Energy Efficient Operation – Optimized internal design minimizes energy loss and heat generation.

| Category | Specification / Details |

|---|---|

| Manufacturer | Moog Inc. |

| Model | D633-7105 |

| Series | D633 Electro-Hydraulic Servo Valve |

| Valve Type | Two-stage, flow control, electro-hydraulic servo valve |

| Technology | Nozzle-flapper with precision spool design |

| Mounting Interface | ISO 10372 / CETOP 3 / NG6 |

| Rated Flow | Typically 38–60 L/min at ΔP = 70 bar (varies by configuration) |

| Maximum Operating Pressure | 315 bar (4560 psi) |

| Return Line Pressure | Max 210 bar |

| Supply Voltage | ±15 VDC (standard for D633 series) |

| Command Signal | ±10 V (typical) |

| Coil Resistance | Approx. 40–60 Ω (depending on coil type) |

| Frequency Response | Up to 150–200 Hz @ -90° phase (depending on load pressure & flow) |

| Hysteresis | < 1% of rated current |

| Null Shift | < 1% |

| Internal Leakage | Typically 0.3–0.7 L/min at 70 bar |

| Hydraulic Fluid | Mineral-based hydraulic oil, ISO 32–68 |

| Fluid Temperature Range | -20°C to +80°C |

| Ambient Temperature | -20°C to +75°C |

| Filtration Requirement | ISO 4406: 16/13 or better |

| Response Type | Fast, dynamic response for precision motion control |

| Ports | P, T, A, B |

| Weight | Approx. 1.0–1.5 kg |

| Electrical Connector | 6-pin Mil-C-5015 or DIN options |

| Applications | Injection molding machines, aerospace test stands, industrial automation, motion control systems |

| Special Features | Excellent repeatability, low hysteresis, high accuracy, robust mechanical design |

| Maintenance | Low maintenance; requires clean hydraulic fluid |