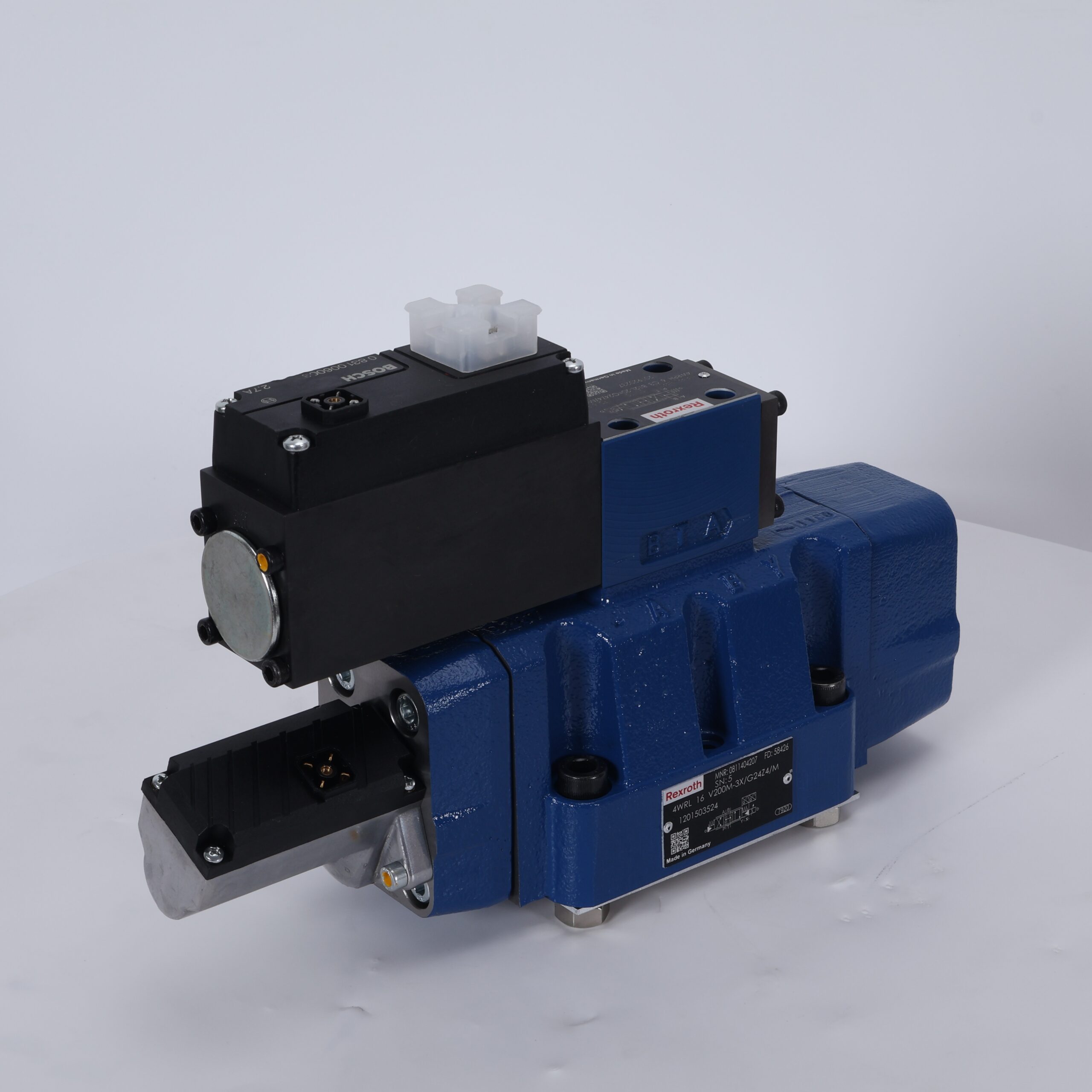

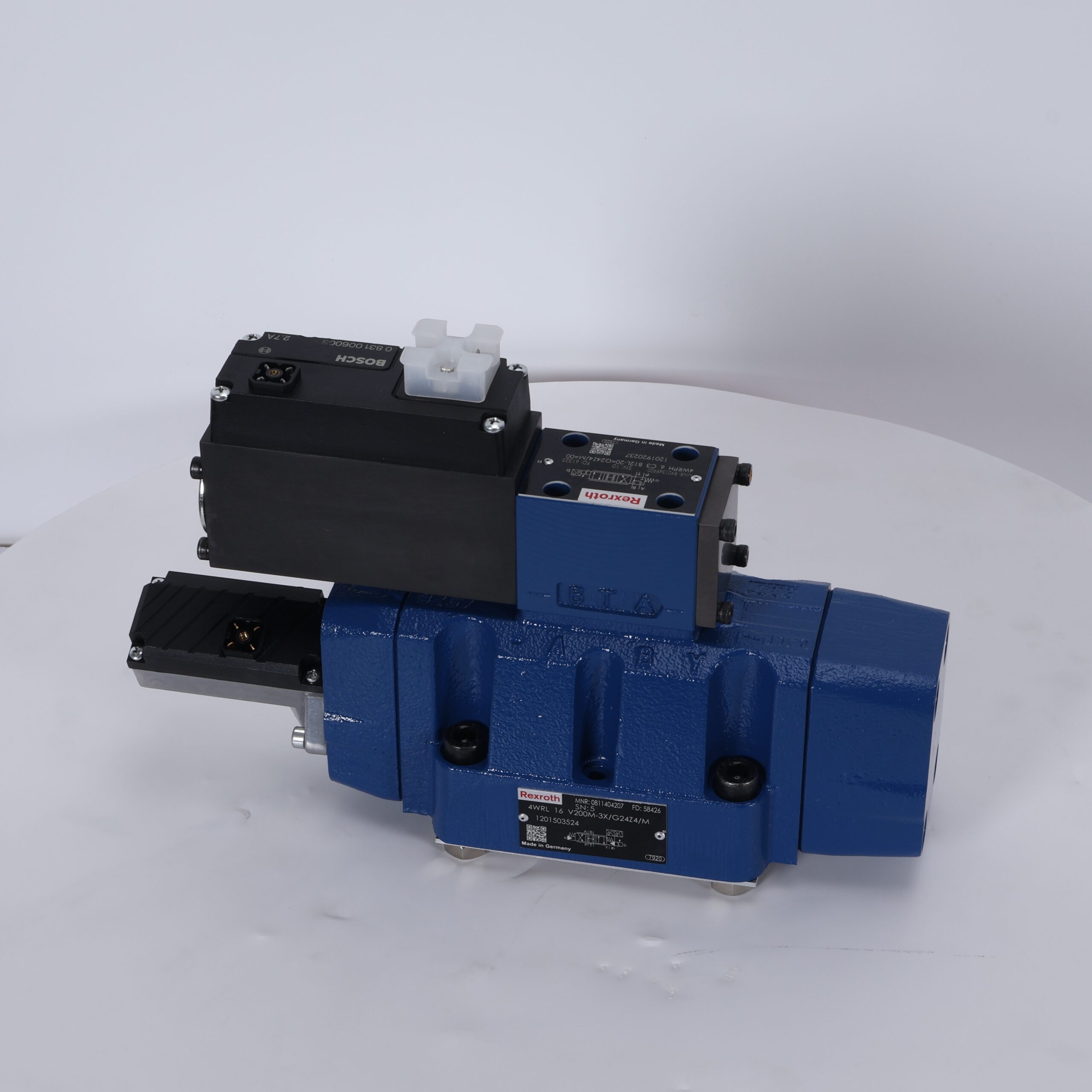

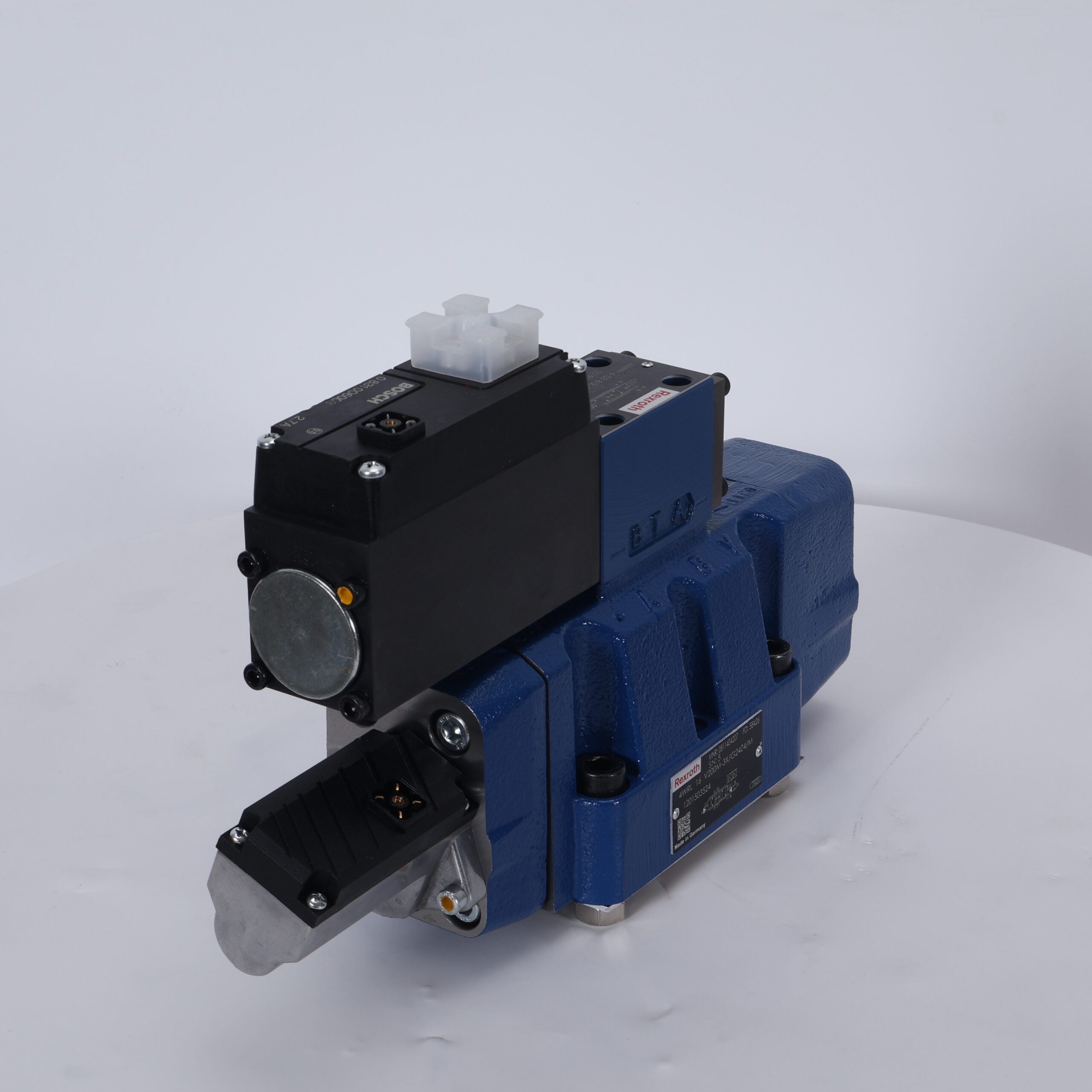

Rexroth 4WRL16 Servo Valve

Description:

share:

YS hydraulic is a leading supplier of hydraulic pumps, valves, and motors, specializing in high-performance solutions for industrial and mobile applications. Our product range includes top brands like Bosch Rexroth, Parker, Moog, and more. With a strong focus on quality and reliability, we provide customers with durable hydraulic systems designed to meet the most demanding requirements. In addition to product supply, we offer comprehensive repair and maintenance services, ensuring optimal performance and minimizing downtime. Our commitment to innovation and customer satisfaction makes us a trusted partner for businesses worldwide.

Key Advantages of Rexroth 4WRL16 Servo Valve

-

Precise control & high performance

-

The valve includes position feedback (via LVDT or similar) on the main spool or stage, which enables accurate control of spool position → consistent, repeatable flow/direction control.

-

The design (pilot-operated, servo quality) allows fine modulation of flow and direction, which is essential in servo-type hydraulic axes.

-

-

Good dynamic response & reliability

-

Servo/proportional valves from Rexroth are engineered for fast response and minimal hysteresis/drift. For example: the HR series “significantly better dynamic response … higher hydraulic switching capacity” (though not exactly the 4WRL16 but indicative of the platform).

-

By controlling spool position electronically and providing feedback, the system can maintain accuracy over time and conditions.

-

Robust industrial design: materials, tolerances and the servo-quality pilot stage help ensure long operational life under demanding loads.

-

-

Integration & flexibility in hydraulic systems

-

The 4WRL series offers mounting to ISO subplate standards (e.g., NG10/NG16 to ISO 4401 variants) making retrofit or new system integration simpler.

-

The electronic feedback and controls allow it to be used with advanced control systems (servo controllers, PLCs, motion control) – important in your business context (hydraulic equipment, control systems).

-

The ability to pick different flow characteristics (linear, progressive) or fail-safe positions in some models.

-

-

Energy efficiency and system optimization

-

By enabling precise control of flow and direction, the valve helps reduce wasted hydraulic energy (less unnecessary flow or overshoot, smoother transitions).

-

When integrated in well-designed hydraulic circuits, servo-valves can contribute to better system performance, less wear and lower maintenance cost over time.

-

The generic benefits for servo valves include “energy efficiency … reduces energy consumption by modulating power output to match operational needs”.

-

-

Suitability for demanding applications

-

The 4/3 directional servo valve data (for similar series) show nominal flows up to ~80-1100 L/min (size NG10-35) and pressures up to ~315-350 bar.

-

The 4WRL16 size sits in the NG16 range; meaning it is suited for moderate to high flow/pressure hydraulic systems (industrial machines, presses, automation) rather than only small pilot flows.

-

This makes it well matched for your market (liquid-hydraulic equipment) where robust, high-performance valves are needed.

-