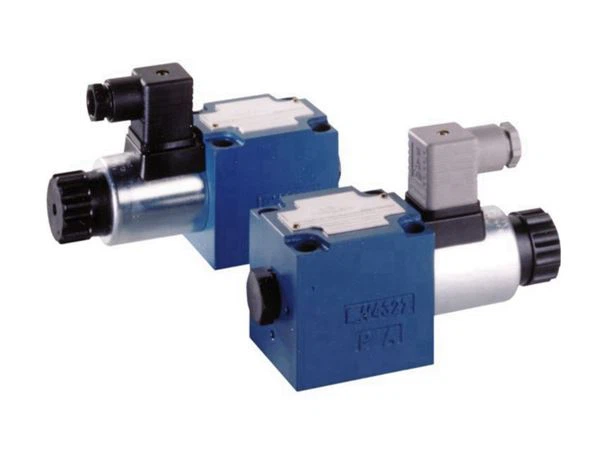

Rexroth Directional Poppet Valve M-3SED

Description:

share:

Rexroth Directional Poppet Valve M-3SED Description

Advantages of the Rexroth Directional Poppet Valve M-3SED

-

Zero-Leak Design

Poppet-seat construction ensures leak-free shutoff for high-safety applications. -

High Pressure Capability

Supports continuous operation at high system pressures typical in industrial and mobile hydraulics. -

Reliable Load Holding

Ideal for systems requiring precise holding without pressure drop. -

Compact & Durable Structure

Rugged body with hardened internal components for long service life. -

Low Internal Leakage & High Efficiency

Improves system efficiency and reduces energy loss. -

Versatile Configuration

Available in multiple switching types, voltage options, and mounting patterns.

| Parameter | Specification / Details |

|---|---|

| Type | Directional Poppet Valve |

| Series | M-3SED |

| Manufacturer | Bosch Rexroth |

| Function | Direct-operated, solenoid-actuated, poppet-type directional control |

| Mounting Interface | NG6 / CETOP 3 / ISO 4401 |

| Maximum Operating Pressure | Up to 350 bar |

| Flow Rate Capacity | Up to 25 L/min (depending on variant) |

| Switching Type | 2/2-way, 3/2-way poppet versions |

| Actuation | Wet-pin DC or AC solenoid |

| Voltage Options | 12V DC, 24V DC, 110V AC, 220V AC |

| Fluid Type | Mineral oil (HL, HLP) and compatible hydraulic fluids |

| Viscosity Range | 10 – 800 mm²/s |

| Temperature Range | –20°C to +80°C |

| Sealing Material | NBR or FKM |

| Leakage | Zero leakage (poppet closed) |

| Response Time | Fast switching time (model dependent) |

| Porting | ISO 4401-03-02 mounting surface |

| Electrical Connection | DIN EN 175301-803 plug |

| Applications | Load holding, clamping systems, presses, safety-critical circuits |

| Maintenance | Low-maintenance, serviceable solenoid assembly |