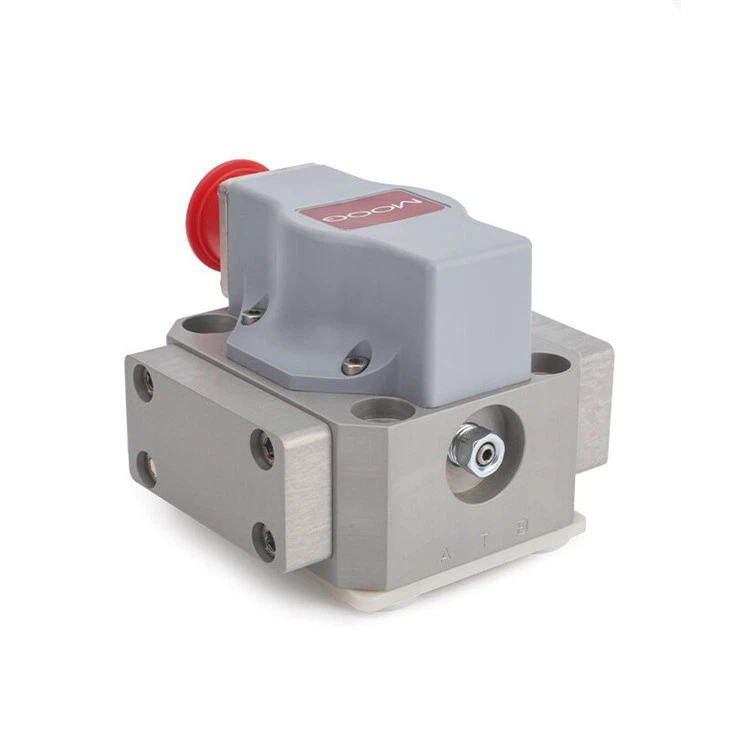

Moog G761‑3033B Servo Valve

Description:

share:

Advantages of the Moog G761‑3033B Servo Valve

-

High Dynamic Performance

Thanks to the two-stage design (pilot + main spool), the G761‑3033B offers rapid step response (< 4 to < 16 ms depending on variant). -

Exceptional Accuracy & Resolution

The mechanical feedback system uses a carbide ball-on-wire (“ball-in-hole”) design, ensuring high accuracy, low hysteresis, and long life. -

Robust Construction

Available in durable cast-iron or aluminum bodies, the valve supports high pressure (up to 315 bar for aluminum, 350 bar for steel) for demanding environments. -

Wide Flow Range

Rated flow spans from approximately 4 to 63 L/min (1 to 16.5 gpm) at a nominal pressure drop, accommodating a broad set of hydraulic applications. -

Compact and Versatile Mounting

The valve follows the ISO 10372-04-04-0-92 mounting pattern, enabling easy integration in compact hydraulic systems. -

Long Service Life

The carbide feedback ball and brazed construction significantly extend operational life under high load and temp conditions. -

Safety Variants Available

Intrinsically safe and explosion-proof versions (G761K, etc.) exist for hazardous environments.

| Parameter | Specification |

|---|---|

| Valve Type | 2‑stage flow control servo valve (mechanical feedback) |

| Pilot Stage | Nozzle-flapper torque motor |

| Main Stage | Four-land sliding spool |

| Mounting Pattern | ISO 10372‑04‑04‑0‑92 |

| Rated Flow | ~4 – 63 L/min (1 – 16.5 gpm) @ Δp = 35 bar/spool land |

| Maximum Operating Pressure | – Ports P/A/B/X: Aluminum body = 315 bar; Steel body = 350 bar – Port T (return): 210 bar (per catalog) |

| Step Response Time (0‑100% stroke) | < 4 ms (very high response) to < 16 ms (standard) depending on variant. |

| Rated Input Signal | 8 – 200 mA (depending on configuration) |

| Electrical Connector | MS3106F14S-2S (or equivalent) per installation manual. |

| Feedback Mechanism | Mechanical feedback via carbide ball-on-wire. |

| Body Material | Cast iron (or aluminum/steel variants) |

| Weight | ~1.0 – 1.7 kg (2.2 – 3.8 lbs) depending on body style. |

| Mounting Surface Finish | ≤ 32 µin; flatness within ±0.03 mm TIR. |

| Null Adjust | Flow adjust can be tuned via null adjust screw. |

| Optional Safety Features | Intrinsically safe versions (G761K) certified per FM, ATEX, IECEx, etc. |