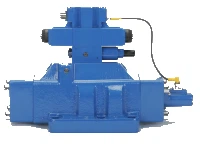

Vickers KBHDG Series Proportional Valves

Description:

share:

Advantages of Vickers KBHDG Series Proportional Valves

-

Integrated electronics & plug-and-play design: On-board amplifier with factory-set gain, deadband compensation and offset deliver reliable and repeatable performance valve-to-valve — reducing setup complexity.

-

High dynamic response and precise control: Spool-position feedback (via LVDT) ensures accurate servo control of flow and pressure, suitable for closed-loop hydraulic circuits requiring stable and responsive operation.

-

Wide hydraulic performance range: Capable of handling high pressures (up to ~315–350 bar) and substantial flows (tens to hundreds of liters per minute), making them versatile for heavy-duty industrial systems.

-

Simplified installation & maintenance: Standard ISO 4401 subplate mounting, 7-pin plug connection, and factory-tuned electronics minimize installation errors and allow quick valve replacement when needed.

-

Robust and reliable under harsh conditions: Designed for industrial applications such as metal forming, injection molding, presses, and more — suitable for demanding environments.

| Parameter | Typical Specification / Details |

|---|---|

| Product Type | Proportional two-stage directional valve |

| Series | KBHDG (e.g. KBHDG5V / KBHDG4V variants) |

| Manufacturer / Brand | Vickers by Danfoss |

| Actuation Type | Solenoid-controlled, pilot operated / directional proportional valve |

| Electrical Supply | 24 V DC (standard) |

| Control Input Signal | ± 10 V command; some models support 4-20 mA command signal option |

| Feedback | Spool-position feedback via LVDT on pilot and/or main stage (servo control) |

| Maximum Pressure | Up to ~315 bar (some models up to ~350 bar / 5000 psi) depending on size and variant |

| Flow Capacity | Example: model KBHDG5V-52C-95N … provides ~95 L/min per A port (≈ 25.1 US gpm) |

| Mounting Interface | ISO 4401 (e.g. NFPA D05 for size 05, etc.) / Subplate mounting |

| Seal Type | Viton (for hydraulic fluids compatibility) |

| Fluid Cleanliness Requirement | 17/15/12 micron or better |

| Fluid Type | Standard anti-wear hydraulic oils (and compatible fluids) |

| Temperature Range (Hydraulic Operating) | Typically from around –20 °C to +70 °C (varies by model) |

| Electrical Connection | 7-pin standard plug connector (factory-wired on-board amplifier) |

| Special Features | Onboard electronics (eliminates separate amplifier), factory-sealed adjustments for valve-to-valve reproducibility, fast dynamic response, wide spool and flow options. |

| Applications | Metal forming, injection/blow molding, hydraulic presses, machine tools, pulp & paper, wood processing, turbine control, marine/offshore, test & simulation. |

| Installation / Maintenance | Subplate mounting; simplified wiring and replacement; minimal external control electronics. |